Sustainable Environment

Corporate Responsibility Practice

ESG Highlights

Climate Change Risks and Actions

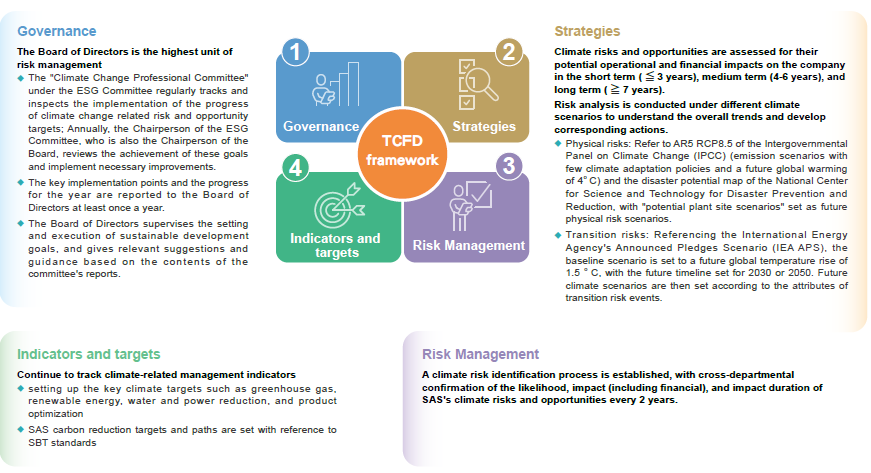

Driven by the pressure of frequent extreme climate events globally and the transition to a low carbon market, SAS is actively addressing the potential risks and opportunities brought by climate change. We refer to the Task Force on Climate-related Financial Disclosures (TCFD) to develop our own climate change risk and opportunity assessment process. Through relevant departments, we collect information on current and emerging policies and regulations, technological and market changes, reputational and physical risks, and execute climate risk and opportunity assessments. This approach aims to understand changes in the external environment and market dynamics, considering the Company’s overall operational strategy planning.

Carbon Emission Management

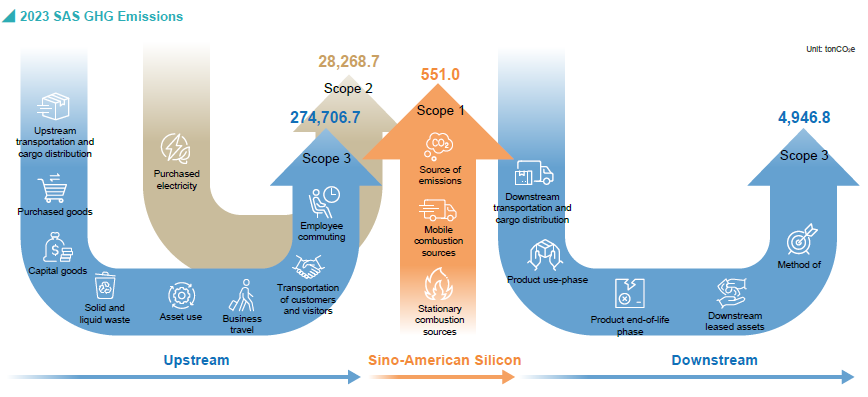

Since 2021, SAS has gradually promoted and completed the systematic GHG emissio ns inventory (ISO 14064-1: 2018) and inventory creation. The reporting boundaries include: the headquarters, Chunan Branch, Yilan Branch, and Hsu-Hsin Branch, wit h 2022 as the baseline year. Each year the greenhouse gas emissions of each plant ar e regularly inventoried and verified by a third party to comprehensivel y understand the emission status and validate the effectiveness of reduction actions. SAS’ Chunan and Yilan branches have adopted the “operational control method” as their organiza tion boundary setting. Greenhouse gas emissions related to organizational operation s include direct (Scope 1, direc t GHG emissions), energy indirect (Scope 2, indirect GHG emissions from imported energy), and other indirect GHG emission sources (Scope 3 to Scope 6). Our greenhouse gasemissions calculations were based on the 7 greenhouse gases defined by the ISO 14064-1 standard: carbon dioxide (CO2), meth ane (CH4), nitrous oxide (N2O), hydrofluorocarbons (HFCs), perfluorocarbons (PFC s), sulfur hexafluorid e (SF6), and nitrogen trifluoride (NF3). We have primarily ado pted the “emission coefficient method.” The emission factors referenced are from the EPA’s GHG Emission Factor Management Table version 6.0.4, the EPA Carbon Foo tprint Calculation Service Platform, the Industrial Technology Research Institute’s DoITPro database, and relevant literature. The Global Warming Potential (GWP) va lues used in the calculation process by Sino-American Silicon Products Inc. (SAS) ar e referenced from the IPCC AR5 (2013) GWP values. The greenhouse gases produced include CO2, CH4, N2O, and HFCs, with no greenhouse gas emissions from perfluor inated compounds.

Energy Management

Most of the past energy-conservation improvements in the factories were onetime improvement efforts, which may not maximize the energy-saving effect due to the lack of an appropriate management mechanism. Thus, since 2021, SAS has gradually implemented an Energy Management System (ISO 50001:2018) in its production facilities. Both the Chunan and Yilan branches have established a systematic PDCA management cycle that inventories equipment energy usage in the factory to identify major energy-using equipment, prioritizes equipment improvement, monitors the measurements, and adopts appropriate improvement actions. Moreover, it helps set corresponding energy baselines and energy performance indicators according to the factory characteristics and energy use identification results as well as continues to update, monitor, and review their reasonableness each month to continuously improve energy efficiency.

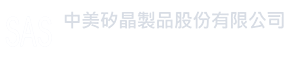

Renewable Energy Layout

SAS has continued to pay attention to the various climate action plans after the Paris Agreement, and TSMC has joined RE100. SAS knows that the construction and use of renewable energy is a necessary and important method for companies to achieve SBT reduction goals. In terms of strategic layout, SAS has deployed its Hsu-Hsin Branch and Yilan Branch (which established the Power Station Development Department in 2020) to fully enter Taiwan’s renewable energy market by actively planning and investing in the construction of roof-, ground-, and water-surface-type solar power plants. The Company has also introduced a water surface buoyancy solar power generation system to lower the water surface temperature and significantly increase the solar panel as well as power generation efficiency. From the beginning (2014) to the end of 2023, the total solar power generation system installation capacity at home and abroad for grid-connected operation is approximately 158.4 MW, with a total annual power generation capacity of 183,937,696 kWh and an estimated carbon dioxide emission reduction of approximately 91,049 metric tons Note. Furthermore, in response to the government’s active promotion of renewable energy, the goal is to complete 20 GW of solar energy installations by 2025. SAS has remained committed to both providing energy management-related services and investing in the construction of solar power plants since 2019.We have stepped up to become a provider of green energy. In 2023, we collaborated with Hitachi Air Conditioner to plan to install a solar power system with a total installed capacity of 9.6MW at the “Hitachi Air conditioner Taoyuan Factory”, the largest air conditioner manufacturer in Taiwan, of which 7MW has been paralleled with Taiwan Power Company officially put into operation.

Management Mechanism

- Through the implementation of the ISO 14001 environmental management system (2015 version) and the adoption of product life cycle concepts, SAS aims to achieve a genuine reduction of materials at the source by relying on improvements in the manufacturing process and product design stages. Cooperated with the promotion on environment management system, we established the goals for energy conservation and material conservation and constantly implement water recycling and waste reduction measures to cherish our resources as well as to achieve the outcome of reducing greenhouse gas emission. Regarding the prevention against air pollution and water pollution, we regularly maintain and patrol on pollution prevention equipment and maintain the treatment performance of equipment. In addition, to enhance the treatment efficiency of acid exhaustion gas in Yilan plant, we purchased a new set of washing tower in 2019 to increase the treatment and detention period of the exhaustion gas. With respect to waste management, traditional cleaning and disposal are transferred into the concept of effective resource management in order to reduce waste generation. Meanwhile, audit management on waste clearance companies is enhanced to ensure that waste is disposed in an appropriate manner. SAS insists on stringent compliance with all relevant laws and regulations in its operations and conducts conformity assessments for all internal and external issues related to the environment. Should any legal risks be detected, detected, immediate, preventive improvement measures are carried out and policy implementation is ensured through comprehensive management and actual operations.

Future Goals

- Renewable energy use target achievement phases: 20% by 2030, 35% by 2035, 50% by 2040, 100% by 2050

- Chunan Branch annual power saving rate > 1% , Yilan branch annual power saving rate1.5%

- Chunan branch introduced factory smart energy management

- Chunan Branch recycled over > 50% of the wastewater from drilling process

- Chunan branch and Yilan branch’s waste recycling rate for the whole plant has reached 85%

- Wastewater diversion in Yilan Branch reduces the inflow of water into the biological wastewater system by more than 50%.

2023 Key Achievements

- The energy-saving measures and management of Chunan and Yilan branches can reduce approximately 3,419 tons of carbon dioxide emissions.

- Yilan branch introduced the ISO 50001 power management system.

- Chunan Branch annual power saving rate > 1%, Yilan Branch annual power saving rate ≧ 800,000 kWh.

- Reduced the dosage of single calcium carbonate and calcium chloride tablets by 10% in the wastewater treatment of the Yilan Branch.

- The air, water, and waste pollution prevention and treatment is in 100% compliance with laws and regulations.

- Chunan Branch recycled over 50% of the wastewater from drilling process